PU (POLYURETHANE)

Polyurethane(PU) is a material that encompass both the properties of rubber and plastic. PU is highly resistance to abrasion and impact, it also offers a certain degree of elasticity similar to rubber It is also resistant to flex fatigue and have the ability of bear heavy load.

-High Elasticity, Tear Resistance

-Good Load Bearing Capability

-Excellent Abrasion Resistance

-Good Impact Resistance

-Weather Resistance

-Does not react well with Oil and Solvent

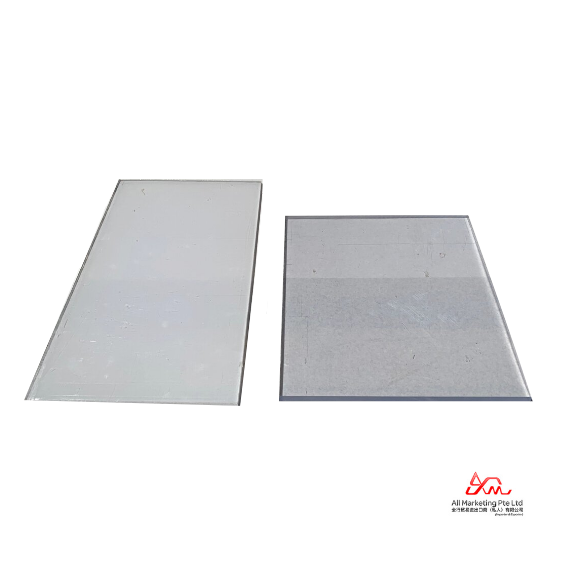

PC (POLYCARBONATE)

PC (PolyCarbonate) – PolyCarbonate can be easily process, machined and thermoformed. Due to these properties, PC is extensively used in many different industries and application. Some of its properties includes:

– Excellent impact resistance

– Excellent Strength and toughness

– Good dimensional stability

– High transparency

– Good electrical insulation

– Good heat resistance

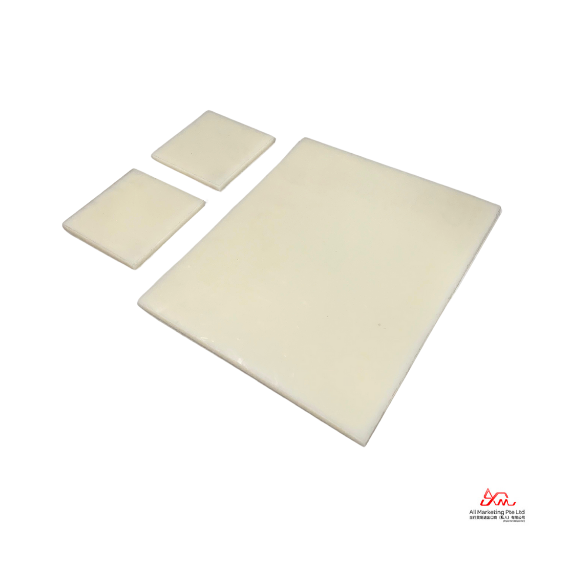

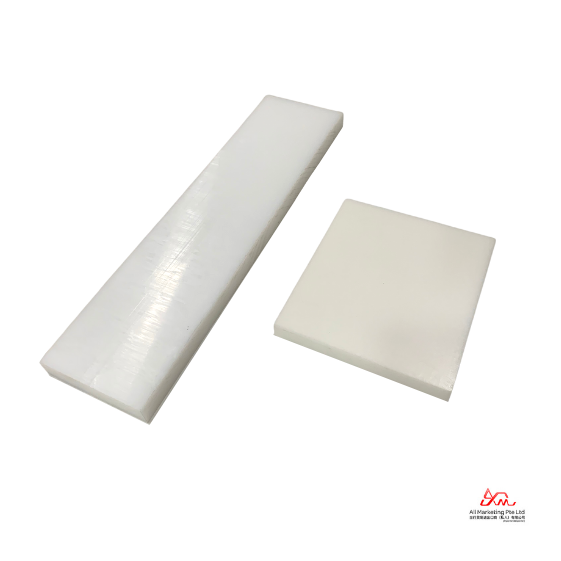

PE / HDPE / UHMWPE (POLYETHYLENE)

PE (Polyethylene) – Polyethylene is a general thermoplastic with good chemical resistance and elongation properties. PE also have good insulation properties and is one of the material choice for plastic welding application. HDPE and UHMWPE are available for applications with more demanding material properties in terms of mechanical strength. Some of its properties includes:

– Good chemical resistance

– Easy to work on

– Low frictional coefficient

– Good electrical insulation

– High toughness and Stiffness (HDPE/UHMWPE)

– Low moisture absorption (UHMWPE)

– High impact strength (UHMWPE)

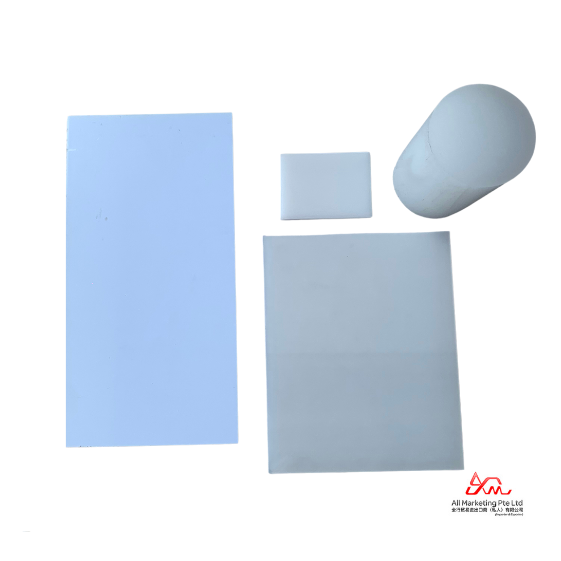

PP (POLYPROPYLENE)

PP (Polypropylene) – Polypropylene is a plastic that is used in many different industries. One of the common usage for polypropylene is to make laboratory equipment that require frequent sterilisation by heat. Its high resistance against temperature makes it an ideal material for this kind of application. Other properties includes:

– Good mechanical strength

– Good corrosion resistance

– Heat resistance

– Good resistance to fatigue

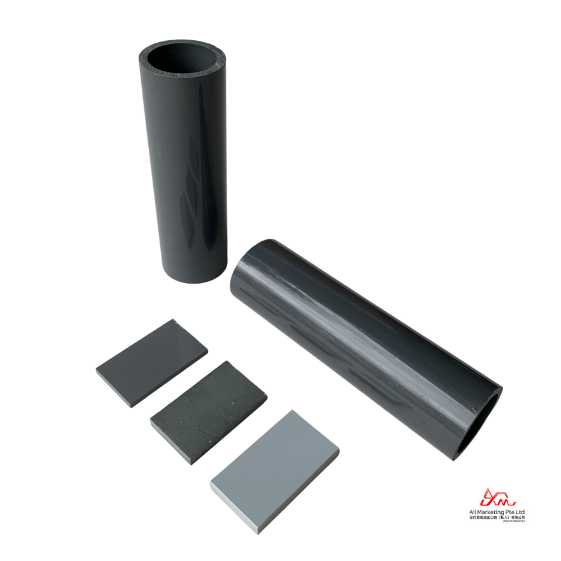

PVC (POLYVINYL CHLORIDE)

PVC is one of the most used general plastic, it has one of the best ratios of economic cost to performance. Application for PVC ranges from applications in daily life all the way to specialized industrial applications. Some of PVC properties include:

– Good dimension stability

– Self-extinguishing

– Electrical insulation

– Corrosion resistance

– Light Weight

– Low Moisture Absorption

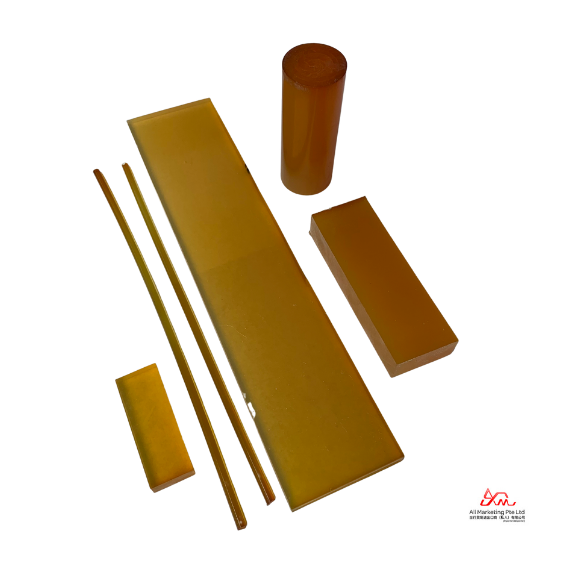

PA6G / PA6 (CAST NYLON / NYLON)

Nylon/ Cast Nylon has a higher compression strength and impact resistance as compared to other engineering plastics. Some of Nylon’s properties includes:

-Corrosion and wear resistance

-Improved component working life and reducing maintenance

-High toughness

-High mechanical strength

-High fatigue resistance

-Shock absorbant and resistance

-Self lubrication and good noise dampening

POM / DELRIN

POM is a general purpose engineering plastics as it is easily machinable, it is also one of the preferred choices when comes to cost sensitive low frictional application. POM properties includes:

– High strength, stiffness, surface hardness

– Good dimension stability and toughness

– Resistance against fatigue, solvent, fuel, abrasion, wear and friction.

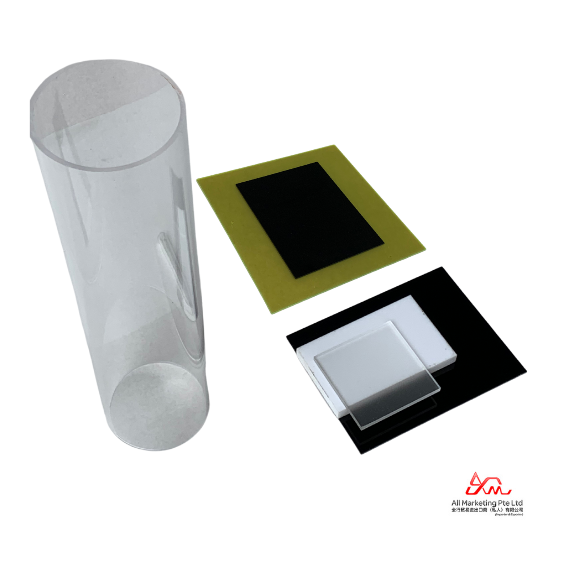

ACRYLIC SHEETS AND RODS

Acrylic – Most commonly use plastic material, Acrylic is a preferred choice for mostly aesthetic purposes due to its attractive finishing. Its properties includes:

– Allowing more than 90% of light transmission

– Light weight

– Easy to work on

– Good thermal insulation

– Low Cost