POM / DELRIN

- Home

- Plastics & Polymers

- POM / DELRIN

POM / DELRIN

FAQ

General Question

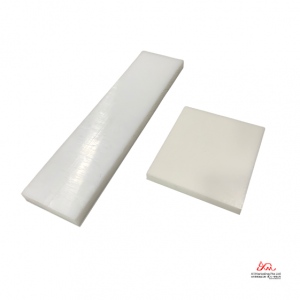

Available in Sheet and Rod form.

Colour: Black, White

Standard Size: Sheet – 1000mm x 2000mm, Rod – 1000mm

Thickness: 1mm to 100mm

Diameter: 4mm to 250mm

POM is widely used in the mechanical, chemical, electrical and aviation sectors. It is particularly suitable for substituting metal precision components in technical uses such as wheelwork, levers, bearings, screws, coils, textile, machine components, pipe fittings, hot water or fuel pump components and manufactured articles. Common POM applications includes Gears, Bearing, Conveyors, Window Guides, Speaker Grilles, Medical Devices, Fasteners and Furniture Component.

Yes! We provide cutting services upon request.

PA6G / PA6 (CAST NYLON / NYLON)

Nylon/ Cast Nylon has a higher compression strength and impact resistance as compared to other engineering plastics. Some of Nylon’s properties includes:

-Corrosion and wear resistance

-Improved component working life and reducing maintenance

-High toughness

-High mechanical strength

-High fatigue resistance

-Shock absorbant and resistance

-Self lubrication and good noise dampening

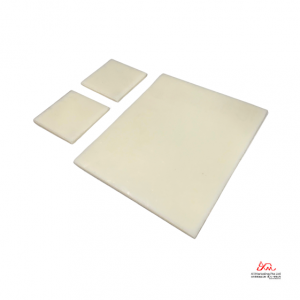

PE / HDPE / UHMWPE (POLYETHYLENE)

PE (Polyethylene) – Polyethylene is a general thermoplastic with good chemical resistance and elongation properties. PE also have good insulation properties and is one of the material choice for plastic welding application. HDPE and UHMWPE are available for applications with more demanding material properties in terms of mechanical strength. Some of its properties includes:

– Good chemical resistance

– Easy to work on

– Low frictional coefficient

– Good electrical insulation

– High toughness and Stiffness (HDPE/UHMWPE)

– Low moisture absorption (UHMWPE)

– High impact strength (UHMWPE)

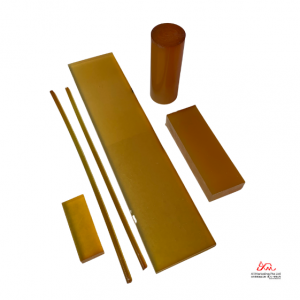

PU (POLYURETHANE)

Polyurethane(PU) is a material that encompass both the properties of rubber and plastic. PU is highly resistance to abrasion and impact, it also offers a certain degree of elasticity similar to rubber It is also resistant to flex fatigue and have the ability of bear heavy load.

-High Elasticity, Tear Resistance

-Good Load Bearing Capability

-Excellent Abrasion Resistance

-Good Impact Resistance

-Weather Resistance

-Does not react well with Oil and Solvent

NOTE: All of the information, suggestions and recommendations pertaining to the properties and uses of the product described herein are based upon tests and data believed to be accurate; however, the final determination regarding the suitability of the material described herein for the use contemplated, the manner of such use, and whether the use infringes any patents is the sole responsibility of the user. THERE IS NO WARRANTY, EXPRESS OR IMPLIED, INCLUDING, WITHOUT LIMITATION WARRANTY OF MERCHANTABILITY OF FITNESS FOR A PARTICULAR PURPOSE. Under no circumstances shall we be liable for incidental or consequential loss or damage. For details and quotations, Contact us at sales@allmarketing.com.sg.