CDM PALLET CARRIER MATERIAL

- Home

- Case Details

- CDM PALLET CARRIER MATERIAL

CDM PALLET CARRIER MATERIAL

FAQ

General Question

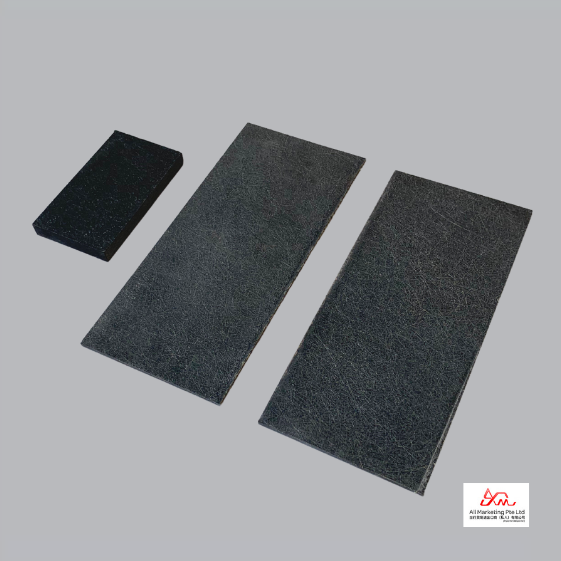

CDM is available in Sheet form.

- Colour: Black

- Standard Size: 1350mm x 2350

- Thickness: 3mm to 14mm

CDM is widely used in the electronics industry for making solder pallet

Yes! We provide cutting services upon request.

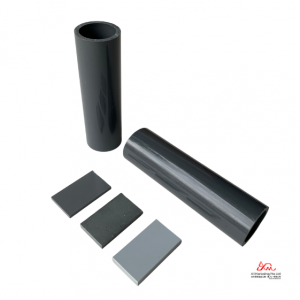

POM / DELRIN

POM is a general purpose engineering plastics as it is easily machinable, it is also one of the preferred choices when comes to cost sensitive low frictional application. POM properties includes:

– High strength, stiffness, surface hardness

– Good dimension stability and toughness

– Resistance against fatigue, solvent, fuel, abrasion, wear and friction.

PVC (POLYVINYL CHLORIDE)

PVC is one of the most used general plastic, it has one of the best ratios of economic cost to performance. Application for PVC ranges from applications in daily life all the way to specialized industrial applications. Some of PVC properties include:

– Good dimension stability

– Self-extinguishing

– Electrical insulation

– Corrosion resistance

– Light Weight

– Low Moisture Absorption

PAPER/ CLOTH PHENOLIC LAMINATE

Paper/ Cloth Phenolic Laminate – Commonly known as Bakelite, are available in two different bases, paper and cloth. Bakelite is typically used for its resistant properties against heat, sound, chemical, friction and electrical non-conductivity.

NOTE: All of the information, suggestions and recommendations pertaining to the properties and uses of the product described herein are based upon tests and data believed to be accurate; however, the final determination regarding the suitability of the material described herein for the use contemplated, the manner of such use, and whether the use infringes any patents is the sole responsibility of the user. THERE IS NO WARRANTY, EXPRESS OR IMPLIED, INCLUDING, WITHOUT LIMITATION WARRANTY OF MERCHANTABILITY OF FITNESS FOR A PARTICULAR PURPOSE. Under no circumstances shall we be liable for incidental or consequential loss or damage. For details and quotations, Contact us at sales@allmarketing.com.sg.