GLASTHERM THERMAL INSULATION MATERIAL

- Home

- Case Details

- GLASTHERM THERMAL INSULATION MATERIAL

GLASTHERM THERMAL INSULATION MATERIAL

FAQ

General Question

Glastherm is available in sheet form.

- Colour: Beige

- Standard Size: 1220mm x 2440mm

- Thickness: 6mm to 25mm

Glastherm is commonly used in mold insulation applications.

Yes! We provide cutting services upon request.

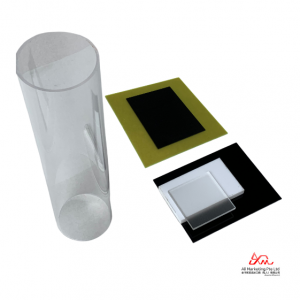

ACRYLIC SHEETS AND RODS

Acrylic – Most commonly use plastic material, Acrylic is a preferred choice for mostly aesthetic purposes due to its attractive finishing. Its properties includes:

– Allowing more than 90% of light transmission

– Light weight

– Easy to work on

– Good thermal insulation

– Low Cost

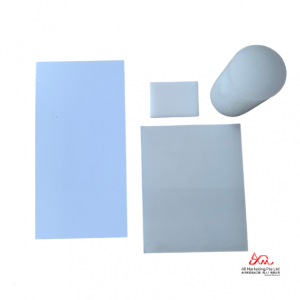

PP (POLYPROPYLENE)

PP (Polypropylene) – Polypropylene is a plastic that is used in many different industries. One of the common usage for polypropylene is to make laboratory equipment that require frequent sterilisation by heat. Its high resistance against temperature makes it an ideal material for this kind of application. Other properties includes:

– Good mechanical strength

– Good corrosion resistance

– Heat resistance

– Good resistance to fatigue

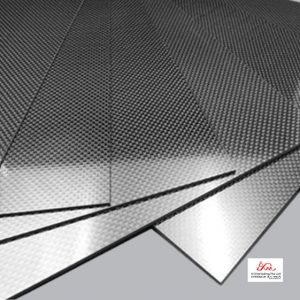

CARBON FIBRE REINFORCED SHEET

Carbon Fibre Reinforced Sheet – Carbon Fibre is known to be one of the strongest yet lightweight material in the market today. Commonly used in many structural application where product weight is one of the biggest obstacles and will significantly affect the performance of these products. Typically used for spare parts or event body structure of products such as Unmanned Aerial Vehicle (UAV), RC Vehicle, High Performance Bicycle and etc.

NOTE: All of the information, suggestions and recommendations pertaining to the properties and uses of the product described herein are based upon tests and data believed to be accurate; however, the final determination regarding the suitability of the material described herein for the use contemplated, the manner of such use, and whether the use infringes any patents is the sole responsibility of the user. THERE IS NO WARRANTY, EXPRESS OR IMPLIED, INCLUDING, WITHOUT LIMITATION WARRANTY OF MERCHANTABILITY OF FITNESS FOR A PARTICULAR PURPOSE. Under no circumstances shall we be liable for incidental or consequential loss or damage. For details and quotations, Contact us at sales@allmarketing.com.sg.