AMLITE WAVE SOLDERING PALLET MATERIAL

- Home

- Case Details

- AMLITE WAVE SOLDERING PALLET MATERIAL

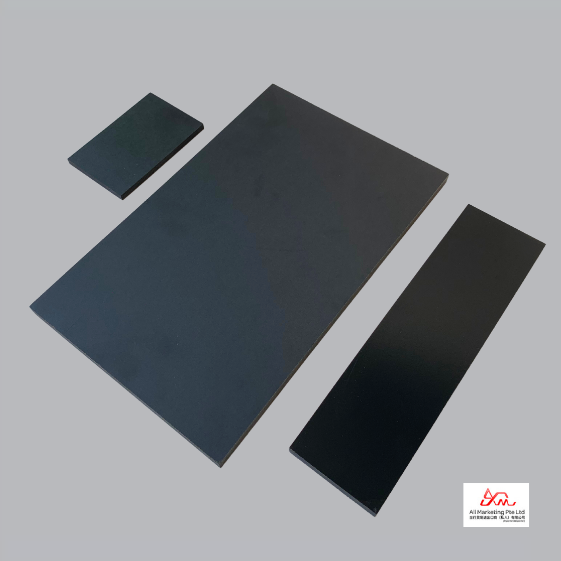

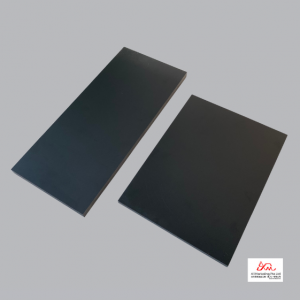

AMLITE WAVE SOLDERING PALLET MATERIAL

FAQ

General Question

Amlite is available in Sheet form.

- Colour: Black

- Standard Size: 1220mm x 1020mm

- Thickness: 2mm to 20mm

Amlite is designed and manufactured to be used for Wave Soldering Pallet material.

Yes! We provide cutting services upon request.

RISS CF-50 TAPPING & CUTTING FLUID

Riss Tapping and Cutting Fluid – Riss Tapping and Cutting Fluid is different from other EP fluid as it does not contain sulfur phosphorus or chlorine. This will help to prevent stain and increase sump life of the machine. Other properties for Riss Tapping and Cutting Fluid includes:

– Stain resistance

– Improved surface finishing

– Foam resistance

– Good tool life

– Fine rust protection

– Quick heat transfer

ESD GLASS EPOXY LAMINATE (ESD G10)

ESD G10 is use in environment where static electricity is undesirable. It is an additional anti-static layer added on to the original G10, erasing and preventing static electricity, and protecting influence from static electricity during the production process.

POM / DELRIN

POM is a general purpose engineering plastics as it is easily machinable, it is also one of the preferred choices when comes to cost sensitive low frictional application. POM properties includes:

– High strength, stiffness, surface hardness

– Good dimension stability and toughness

– Resistance against fatigue, solvent, fuel, abrasion, wear and friction.

NOTE: All of the information, suggestions and recommendations pertaining to the properties and uses of the product described herein are based upon tests and data believed to be accurate; however, the final determination regarding the suitability of the material described herein for the use contemplated, the manner of such use, and whether the use infringes any patents is the sole responsibility of the user. THERE IS NO WARRANTY, EXPRESS OR IMPLIED, INCLUDING, WITHOUT LIMITATION WARRANTY OF MERCHANTABILITY OF FITNESS FOR A PARTICULAR PURPOSE. Under no circumstances shall we be liable for incidental or consequential loss or damage. For details and quotations, Contact us at [email protected].

- 61 Kaki Bukit Ave 1, #01-07 Shun Li Industrial Park, Singapore 417943

- [email protected]

- (+65) 6844 4662

Powered by Beta Werkz Pte Ltd

Copyright © 2022 All rights reserved.