GLASS EPOXY LAMINATED SHEETS & RODS (FR4/G10/G11)

- Home

- Case Details

- GLASS EPOXY LAMINATED SHEETS & RODS (FR4/G10/G11)

GLASS EPOXY LAMINATED SHEETS & RODS (FR4/G10/G11)

FAQ

General Question

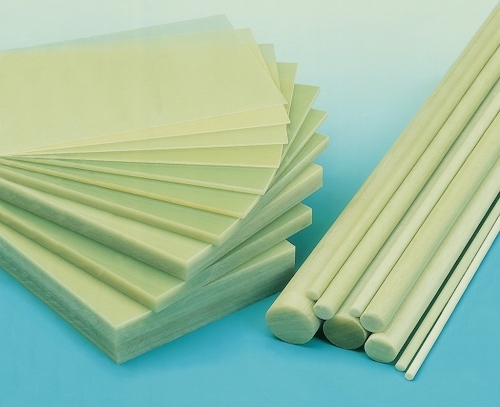

Glass Epoxy Laminate are available in sheet, rod and pipe forms.

- Colour: G10 – Green & Black, G11 – Yellow

- Standard Size: Sheet – 1020mm x 1220mm, Rod – 1000mm

- Thickness: 0.1mm to 80mm

- Diameter: 6mm to 95mm

Appliance Lines, Bearings, Computer Electronics, Electron Lines, Electronic Boards, Gaskets, Gears, Industrial Laminates, Industrial Electronics, Machine Components, Mechanical Lines, Wave Soldering Pallet, Switches, Terminal Boards, Thick Parts, Transformers, Washers, Wear Strips

Yes! We provide cutting services upon request.

We also provide grinding services to improve thickness accuracy of the material.

END MILL

Produced with cutting edge technology, SGO cutting tools are indispensable for today’s manufacturing environment. It is good for machining a wide range of materials ranging from fibre-reinforced polymer to alloy and steel of various hardness. SGO End Mill are available in various flute options and diameters.

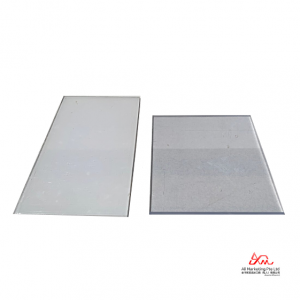

PC (POLYCARBONATE)

PC (PolyCarbonate) – PolyCarbonate can be easily process, machined and thermoformed. Due to these properties, PC is extensively used in many different industries and application. Some of its properties includes:

– Excellent impact resistance

– Excellent Strength and toughness

– Good dimensional stability

– High transparency

– Good electrical insulation

– Good heat resistance

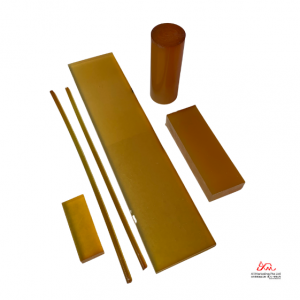

PU (POLYURETHANE)

Polyurethane(PU) is a material that encompass both the properties of rubber and plastic. PU is highly resistance to abrasion and impact, it also offers a certain degree of elasticity similar to rubber It is also resistant to flex fatigue and have the ability of bear heavy load.

-High Elasticity, Tear Resistance

-Good Load Bearing Capability

-Excellent Abrasion Resistance

-Good Impact Resistance

-Weather Resistance

-Does not react well with Oil and Solvent

NOTE: All of the information, suggestions and recommendations pertaining to the properties and uses of the product described herein are based upon tests and data believed to be accurate; however, the final determination regarding the suitability of the material described herein for the use contemplated, the manner of such use, and whether the use infringes any patents is the sole responsibility of the user. THERE IS NO WARRANTY, EXPRESS OR IMPLIED, INCLUDING, WITHOUT LIMITATION WARRANTY OF MERCHANTABILITY OF FITNESS FOR A PARTICULAR PURPOSE. Under no circumstances shall we be liable for incidental or consequential loss or damage. For details and quotations, Contact us at sales@allmarketing.com.sg.