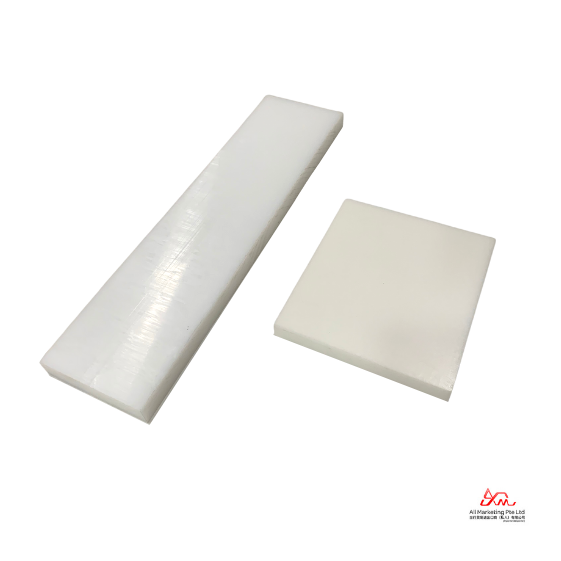

PA6G / PA6 (CAST NYLON / NYLON)

Nylon/ Cast Nylon has a higher compression strength and impact resistance as compared to other engineering plastics. Some of Nylon’s properties includes:

-Corrosion and wear resistance

-Improved component working life and reducing maintenance

-High toughness

-High mechanical strength

-High fatigue resistance

-Shock absorbant and resistance

-Self lubrication and good noise dampening

POM / DELRIN

POM is a general purpose engineering plastics as it is easily machinable, it is also one of the preferred choices when comes to cost sensitive low frictional application. POM properties includes:

– High strength, stiffness, surface hardness

– Good dimension stability and toughness

– Resistance against fatigue, solvent, fuel, abrasion, wear and friction.

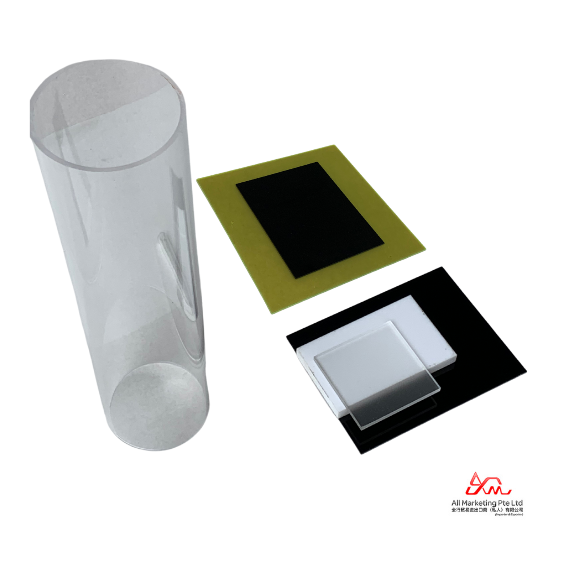

ACRYLIC SHEETS AND RODS

Acrylic – Most commonly use plastic material, Acrylic is a preferred choice for mostly aesthetic purposes due to its attractive finishing. Its properties includes:

– Allowing more than 90% of light transmission

– Light weight

– Easy to work on

– Good thermal insulation

– Low Cost

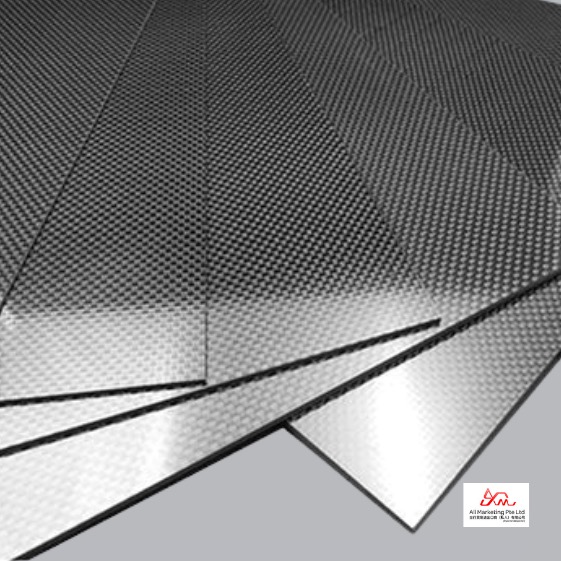

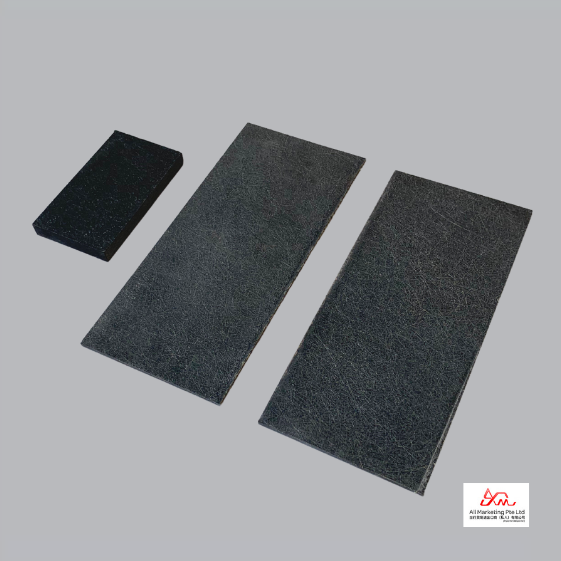

CARBON FIBRE REINFORCED SHEET

Carbon Fibre Reinforced Sheet – Carbon Fibre is known to be one of the strongest yet lightweight material in the market today. Commonly used in many structural application where product weight is one of the biggest obstacles and will significantly affect the performance of these products. Typically used for spare parts or event body structure of products such as Unmanned Aerial Vehicle (UAV), RC Vehicle, High Performance Bicycle and etc.

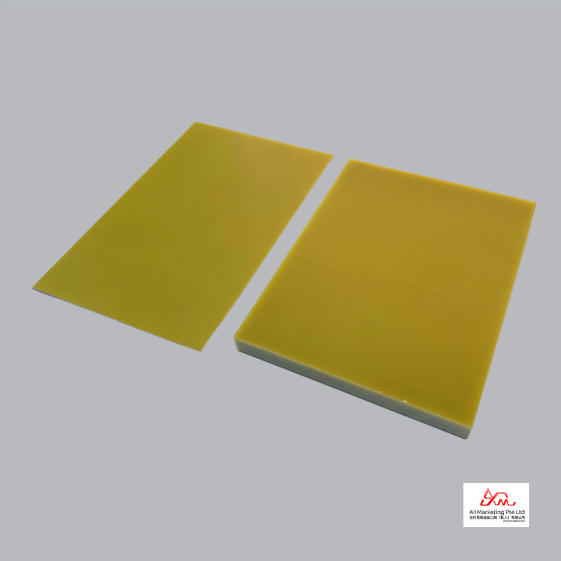

AMLITE WAVE SOLDERING PALLET MATERIAL

Amlite Material – By using woven glass fabric as the base and an extra high temperature resistance formula chemical resin, Amlite is designed and manufactured to be used for Wave Soldering Pallet material. It’s short-term high temperature resistance of 380°C is good against thermal shock that can happen during the process and excellent machinability and durability makes it a preferred choice over other materials for this application.

Amlite is also equipped with homogeneous Anti-Static (ESD) properties, making it suitable for use in static sensitive environment even after machining.

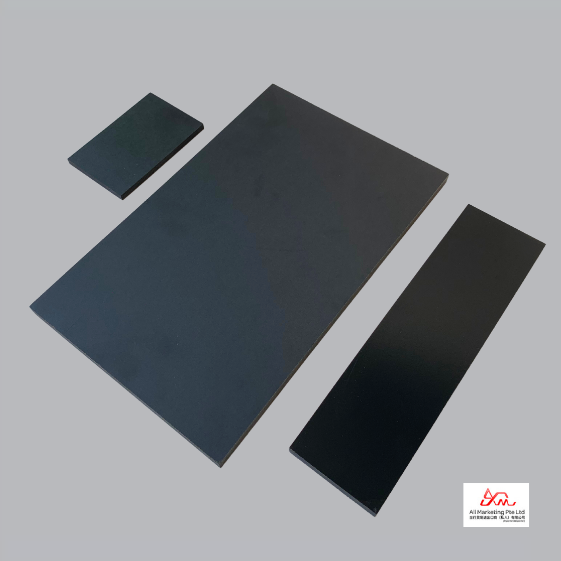

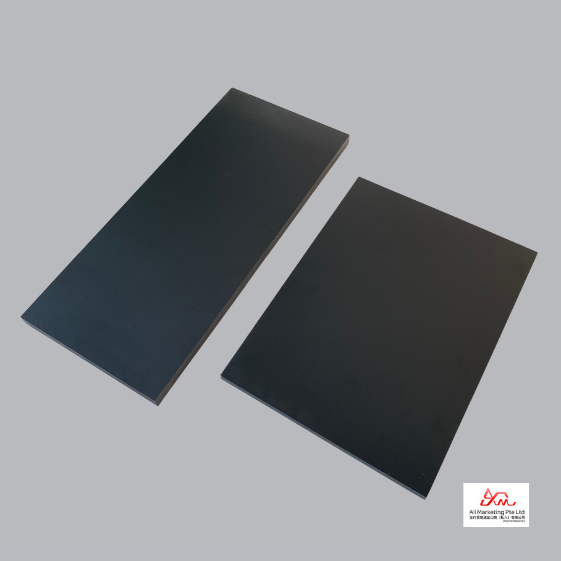

CDM PALLET CARRIER MATERIAL

Composite Delmat Material (CDM) – CDM is widely used in the electronics industry for making solder pallet due to its high temperature resistance, good fabrication qualities, chemical resistance, electrostatic dissipative properties and also the ability to be detectable by sensors.

Even at high temperatures of up to 300 degrees celsius, CDM retains its mechanical strength very well. It is specially designed to prevent deformation, thus maximising the life cycle for extensive production. CDM is also designed for safe working in ESD environment.

GLASTHERM THERMAL INSULATION MATERIAL

Glastherm is commonly used for its excellent heat resisting properties in mold insulation applications. It can withstand up to 280 degrees celsius. Having a strong structural strength/ composition, Glastherm is designed to withstand high molding pressure and rough handling even at process temperatures, it also resist oil and have minimal water absorbtion, and is asbestos-free.

PAPER/ CLOTH PHENOLIC LAMINATE

Paper/ Cloth Phenolic Laminate – Commonly known as Bakelite, are available in two different bases, paper and cloth. Bakelite is typically used for its resistant properties against heat, sound, chemical, friction and electrical non-conductivity.

HALOGEN FREE GLASS EPOXY LAMINATE

Halogen Free (HF) G10 offers a halogen free alternative to the normal G10/ FR4 Glass Epoxy Laminates. Commonly used in PCB boards for consumer electronics such as mobile phone, tablets and many others, HF-G10 is also procured for its properties against toxic smoke in case of fire and provides good performance during lead free soldering.

ESD GLASS EPOXY LAMINATE (ESD G10)

ESD G10 is use in environment where static electricity is undesirable. It is an additional anti-static layer added on to the original G10, erasing and preventing static electricity, and protecting influence from static electricity during the production process.